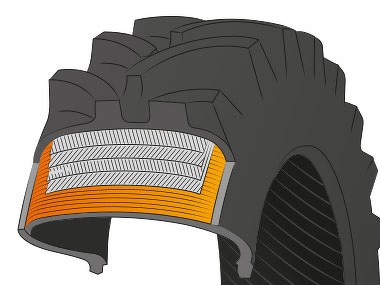

Structure of a radial tyre

Radial casing

OTR tyres are placed under great stress. That is why for OTR tyres especially, the radial casing has to be flexible, stable and strong. This explains the many layers of rayon, nylon, polyester or steel strips that are placed against the driving direction. The radial cords run parallel from heel to heel and at an angle of 90 degrees.

The strength of the casing is determined by:

- The number of strips

- The quality (tensile strength and elasticity) of the strip material

- The number of strip layers

The strength of the casing determines the maximum tyre pressure. In turn, the tyre pressure and air volume determine the maximum load (bearing capacity) that can be placed on the tyre. Different bearing capacities and speeds are encountered for these tyres because the volume of OTR tyres varies greatly per situation.

Belt and strip layers

The casing features a belt that consists of two or more diagonal strip layers. The belt is integrated into the tread, which means its length does not change when driving. The belt and tread help to create a rigid and stable whole.

Tread with pattern

The most talked about section of a tyre is the part which comes into contact with the ground or road surface. The tread is made from rubber and the OTR segment features a huge variety of tread designs, or in other words: patterns. The suitability of a pattern is primarily determined by its ability to offer traction or high resistance against incisions. In addition, the depth of the pattern can differ greatly from tyre to tyre. More about the various versions (e.g. L3/L4/L5) can be found later in this handbook. Rubber used in the tread must always be able to resist tears, bowing, deformation and wear.

Shoulders

The shoulders form the transition between the tread and the side walls.

Side walls

Side walls determine the level of flex, or the flexibility of the casing. This means radial tyres can change shape and absorb shocks. The side walls must be able to effectively resist weather conditions, vibrations and movements. Rubber used in side walls consists of an elastic rubber compound. This rubber protects the casing. Tyre markings are also placed on the side wall of the tyre.

Heels

Heels help to create a connection between the tyre and the rim. This helps to prevent slipping against the rim. The outside of the heel features a breaker, which serves as protection. It also helps to keep out sand and dirt. Due to their relatively large diameter and low rim edge, only limited pressure can be placed inside OTR tyres during assembly. This is referred to as the assembly pressure. The heel can be pushed over the edge of the rim if this pressure is exceeded, which can be very dangerous.

Tubeless layer (TL/TT)

Tyres with inner tubes (Tube-Type) feature a thin, non-airtight layer of rubber on the inside of the casing. This prevents strip layers causing damage to the casing and the inner tube. TubeLess tyres (without inner tube) feature an air-tight layer of rubber on the inside of the casing, which is also referred to as the inner liner or tubeless layer.

> Take a look at our entire range of agricultural tyres

Like to know more?

Do you need advice? Please contact us, our experts will be pleased to assist you. Contact our experts at +31 (0)523 - 850 850 or by e-mail to info@heuver.com. You can read all of our articles on our knowledge-page.