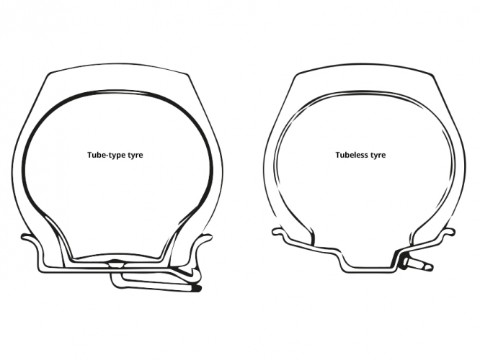

TT or TL- tube type or tubeless tyres

Air improves load capacity

Tyres are the only thing that to come into contact with road surfaces, which means they have a major impact on driving behaviour and handling. Tyres are specially developed considering their under-surface (purpose), generated temperature and their load. The rubber mix and profile of each tyre is also determined with this in mind. Air pressure inside the tyre bears 90% of the load placed upon it. The remaining 10% is borne by the tyre itself.

Tubeless

Tubeless tyres fit perfectly against the special elevated edge (hump) of tubeless wheel rims, which helps to create an air-tight seal. This means special inner edges and rim tape are not needed. The valve has been incorporated into the wheel rim, and features a special rubber seal. These tyres are so compact - in terms of carcase and rubber composition - that no, or only minute amounts of air can escape via the pores.

One of the advantages of tubeless tyres is that they lose air gradually if there is a leak in the carcase – caused by, for example, a nail. As a result, vehicle handling will also decrease gradually, which helps to improve safety. Punctures can often be repaired by placing a tyre plaster on the inside of the carcase, or via vulcanisation in case of severe damage.

Tyres with inner tube

Of the two tyre types (TT and TL), tyres with an inner tube are a more traditional option. In this case, the inner tube - which has its own valve - is placed inside the tyre. Due to the limits for radial and total flexibility identified for each tyre, the inner tube must fit perfectly inside the carcase. If the inner tube is too big, it may fold and result in premature failure. If the inner tube is too small, it could be over-stretched and thus increase the likelihood of tearing and decrease the quality of the seal. If these tyres are punctured, it is cheaper to replace the inner tube rather than the whole (tubeless) tyre.

The risks and areas of focus when using inner tubes are as follows:

- incorrect size (fit between inside of tyre and wheel rim);

- friction between inner tube and carcase, which generates excessive heat (risk of failure);

- sudden loss of air pressure when tyre is punctured (handling and steering);

- protruding inner tube if carcase is damaged (risk of sudden puncture);

- need to use rim tape (this protects against curb stones and irregularities on the wheel rim).

TIP

If tyres are not mounted correctly, this could cause damage to the tyres themselves, as well as the wheel rim, the vehicle and the passengers. Therefore, such activities must be carried out by qualified professionals who possess the required equipment (e.g. a tyre cage).

It is mandatory to always comply with the technical instructions of tyre manufacturers and vehicle constructors, as well as the user instructions for assembly machines and equipment.

Like to know more?

Do you need advice? Please contact us, our experts will be pleased to assist you. Contact our experts at +31 (0)523 - 850 850 or by e-mail to info@heuver.com. You can also read all about trucks on the truck knowledge-page.