Albourgh Tyres launches extended range of solid rubber tyres

Long service life and excellent performance in the toughest environments

The Albourgh Core series sets new standards in solid tyre technology. This series is designed for wheel loaders, material handlers and skid steer loaders used in metal recycling, waste and scrap processing and heavy industry. With a puncture-proof design, exceptional comfort and leading load capacities, the Core series tyres guarantee maximum uptime, where downtime is not an option. The Core series tyres are designed to last and perform excellently during the toughest jobs on solid ground.

Core Grip

Suitable for use on wheel loaders in scrapyards and recycling facilities, the Core Grip offers grip and durability in demanding environments. The Core Grip features two rows of buffer holes for comfort and heat reduction. The tyre is made of a cut-resistant material and the deep tread design ensures maximum traction. Low rolling resistance provides extra fuel efficiency. The Core Grip will be available in sizes 17.5-25 up to and including 29.5-25 and 35/65-33.

Core Twin

The Core Twin is designed for mobile excavators and material handlers. Thanks to the dual mounting, and the associated wide contact surface, this tyre provides good stability and is suitable for applications with high loads. The Core Twin comes with solid rubber spacers, which ensure maximum comfort during heavy load cycles. In combination with reinforced rims, it can handle peak loads and prevents downtime. Available in sizes 10.00-20, 12.00-20 and 12.00-24.

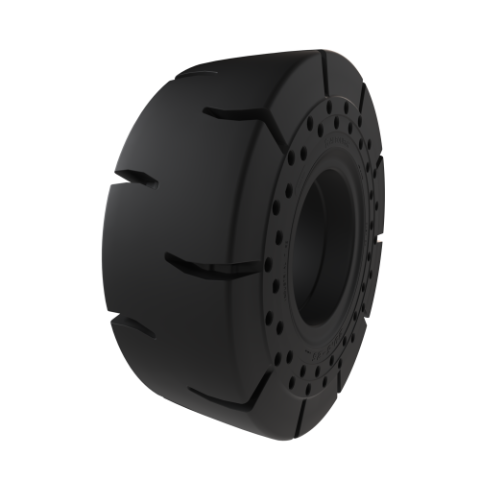

Core Skid

Made for skid steer loaders, the Core Skid has two rows of cooling holes, which reduce vibrations and heat build-up. In combination with a cut-resistant material, the Core Skid can easily handle extreme maneuvers and surface loads. The deep block pattern provides excellent grip. The reinforced compound guarantees a long service life under heavy use and is 100% puncture-proof. The Core Skid is available in the sizes 30x10-16 and 33x12-20; equivalent to the well-known pneumatic tyres in the sizes 10-16.5 and 12-16.5.

Core Lite

The Core Lite is designed for compact wheel loaders and offers optimum maneuverability on recycling and tight construction sites. The double row of damping holes increases the comfort of the driver. The durable tread design offers a high degree of traction and thanks to the lugs, the Core Lite has excellent self-cleaning properties. The Core Lite is released in sizes 15.00-20 and 18.00-20 and is an alternative to the well-known 405/70R18 and 405/70R20 pneumatic tyres.

Unique production process ensures solid quality

The Albourgh Core Series is manufactured on a dedicated production line designed to meet the unique demands of the industry. The production process is automated and monitored to ensure consistent quality. State-of-the-art precision casting ensures that the Core Series maintains the highest dimensional tolerances, while integrated compound control ensures uniformity of each production batch.

Each Core Series tyre features a multi-layer rubber construction for robustness and cushioning, fully integrated perforation technology to reduce heat build-up and improve driver comfort, and a cut and chip resistant compound designed for use on abrasive surfaces such as concrete, metal and waste. If required, Core Series tyres can be supplied with custom-made rims.

After production, each Core Series tyre undergoes a series of stringent quality control checks; visual and dimensional inspections, durometer testing to verify rubber hardness and consistency, static pressure testing by size and application, and compound integrity analysis for temperature and wear behavior. Each tyre is matched to the correct industrial rim and, where applicable, is delivered ready to use, so that each machine can be operated with maximum safety and reliability.